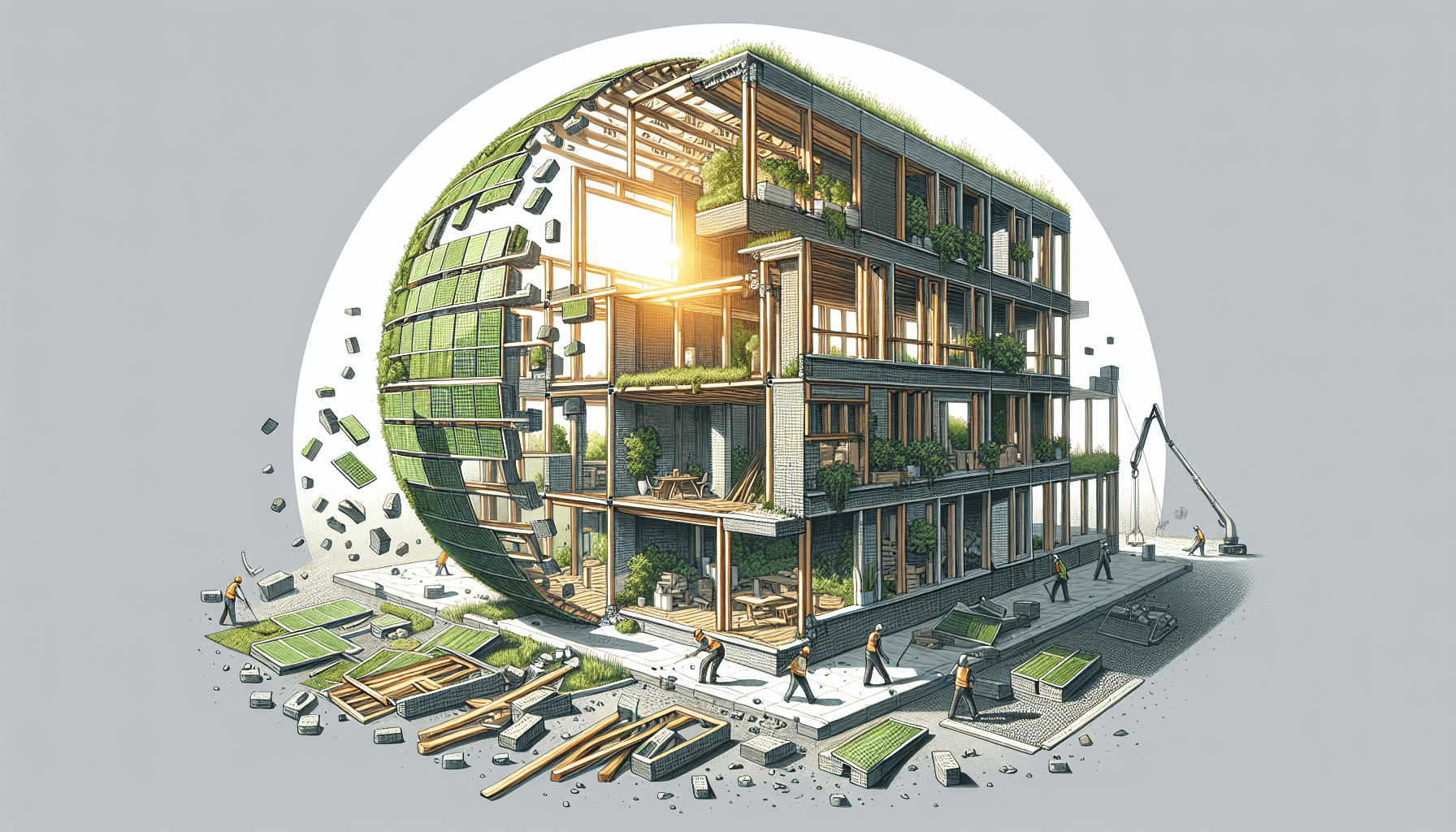

In our journey toward a more sustainable future, we often focus on the design and construction of eco-friendly buildings. But what happens when a building reaches the end of its lifecycle? In the article “How Do You Design For Deconstruction In Sustainable Architecture?”, we explore innovative approaches to ensure that structures can be efficiently disassembled and their materials reused or recycled. By designing with the end in mind, we can minimize waste, reduce our carbon footprint, and contribute to a circular economy. Join us as we delve into the principles and practices that make sustainable architecture truly sustainable from start to finish. How do you design for deconstruction in sustainable architecture?

Introduction

Have you ever wondered how we can make architecture more sustainable? Designing for deconstruction is one promising approach. In an era where environmental concerns are increasingly pressing, it’s time to rethink how we build—and how we can eventually take those buildings apart in ways that are as eco-friendly as possible. Designing for deconstruction is not just a trend; it’s a critical shift towards sustainability.

What is Designing for Deconstruction?

Designing for deconstruction (DfD) involves creating buildings that can be easily dismantled at the end of their life cycle. This method allows for the reuse and recycling of building components, thereby reducing waste and conserving resources. Instead of a building’s demolition being a one-way trip to the landfill, DfD gives materials a second life and significantly curtails environmental impact.

Key Principles of Designing for Deconstruction

- Modularity: Use modular components to make it easier to dismantle.

- Non-toxic materials: Choose materials that can be safely reused or recycled.

- Mechanical connections: Opt for bolts and screws over nails and adhesives.

- Standard dimensions: Utilize standard sizes for ease of replacement.

By implementing these principles, we can contribute to a circular economy in which resources are continuously reused.

The Importance of Sustainable Architecture

Before diving into the technical aspects of DfD, it’s crucial to understand why sustainable architecture is so important. Buildings have a substantial environmental impact, contributing to carbon emissions, deforestation, and resource depletion. Sustainable architecture seeks to minimize these impacts through various strategies, including efficient energy use, renewable materials, and DfD.

Environmental Benefits

Designing for deconstruction offers numerous environmental benefits, such as:

- Reduced Waste: By reusing components, we can significantly reduce the amount of waste that ends up in landfills.

- Resource Conservation: DfD allows materials to be reclaimed and reused, preserving natural resources.

- Lower Carbon Footprint: Reusing materials often requires less energy than producing new ones, reducing greenhouse gas emissions.

Economic and Social Benefits

DfD is not only good for the planet; it’s also advantageous for people and economies.

- Cost Savings: Reusing materials can lower construction costs.

- Job Creation: Deconstruction creates more jobs than demolition due to the labor-intensive process of dismantling.

- Community Impact: Buildings designed for deconstruction can be erected more quickly and safely, benefiting community resilience.

Steps to Design for Deconstruction

Step 1: Choose the Right Materials

Selecting materials that can be easily disassembled, reused, or recycled is the first step in DfD. Materials with a long lifecycle, such as timber, steel, and brick, are excellent choices due to their durability and versatility.

| Material | Advantages | Considerations |

|---|---|---|

| Timber | Renewable, easily reusable | Susceptible to rot and pests |

| Steel | Highly recyclable, durable | Energy-intensive manufacturing |

| Bricks | Long-lasting, can be reused | Heavy, can be labor-intensive |

| Concrete | High compressive strength | Often needs to be downcycled |

| Composites | Lightweight, versatile | Difficult to recycle |

Step 2: Design Modular Systems

Modular building systems simplify the process of assembling and disassembling buildings. By designing units that fit together in standardized ways, we make it easier to replace, reuse, or recycle individual parts.

Step 3: Utilize Mechanical Connections

Instead of using adhesives or welded joints, mechanical fasteners such as screws, bolts, and clips allow for easier disassembly. These connections can be undone without damaging the materials, offering a clear path to future reuse.

Step 4: Incorporate Flexibility and Adaptability

Flexible and adaptable spaces can be easily repurposed, extending the functional life of the building. Designing buildings with open floor plans and movable walls can facilitate changes over time, reducing the need for extensive remodeling.

Step 5: Conduct Life Cycle Assessments

A life cycle assessment (LCA) examines the environmental impact of a building throughout its entire life span. By conducting LCAs during the design phase, we can identify areas for improvement and ensure that the building meets sustainability goals from start to finish.

Common Challenges and Solutions

While the concept of DfD is compelling, it comes with its own set of challenges. But worry not, with challenges come solutions!

Challenge 1: Cost

Solution: Initially, the cost of designing for deconstruction may be higher due to the need for more detailed planning and specialized materials. However, these initial costs can be offset by the reduced expenses in waste disposal and material procurement in the long run.

Challenge 2: Regulatory Barriers

Solution: Many building codes and regulations are not designed with deconstruction in mind. Advocacy and collaboration with regulatory bodies can help update these codes to accommodate sustainable practices.

Challenge 3: Skill Gaps

Solution: Training programs and educational initiatives can help architects, builders, and contractors understand the principles and benefits of DfD. Investing in skill development is crucial for the widespread adoption of these practices.

Challenge 4: Market Demand

Solution: Public awareness campaigns can educate potential clients about the benefits of DfD, driving market demand. Showing tangible benefits, such as cost savings and environmental impact, can make a compelling case for DfD.

Technological Advances in Deconstruction

The field of deconstruction is continuously evolving, thanks in large part to technological innovations. Here’s a look at some game-changing advancements:

Building Information Modeling (BIM)

BIM is a digital representation of a building’s physical and functional characteristics. This tool allows architects to plan and manage every phase of the building’s lifecycle, including deconstruction. By using BIM, we can create detailed plans that make disassembly straightforward and efficient.

Robotics and Automation

Robotic technologies are being developed to assist in the deconstruction process. Drones and specialized robots can help identify materials and dismantle buildings safely and efficiently, reducing human labor and error.

Material Tracking Systems

Emerging technologies such as RFID tags and blockchain can track materials throughout their lifecycle. This not only ensures that materials are used effectively but also facilitates easy identification and retrieval during the deconstruction process.

Virtual Reality (VR) and Augmented Reality (AR)

VR and AR can offer architects and builders a new dimension of understanding in the planning phase. These technologies allow us to visualize how components fit together and how they can be disassembled. This preemptive understanding can mitigate risks and inefficiencies.

Case Studies

Let’s take a look at some real-world instances where designing for deconstruction has been effectively implemented.

Case Study 1: The Circular Building, London

The Circular Building, a project in London, was designed with a focus on DfD. The building used prefabricated timber panels and was assembled with mechanical connections, allowing for easy disassembly. Materials were chosen for their reusability and low environmental impact.

Highlights:

- Modular timber panels

- Reusable mechanical connections

- Low-impact, non-toxic materials

Case Study 2: H16 Sustainability Pavilion, Australia

The H16 Sustainability Pavilion in Australia serves as another standout example. Designed for flexibility, the pavilion can be relocated, reconfigured, or fully dismantled. Its construction utilized steel and glass, with emphasis on detachable connections.

Highlights:

- Movable, flexible structure

- Steel and glass construction

- Detachable connections

Case Study 3: Bullitt Center, Seattle

Although not entirely designed for deconstruction, the Bullitt Center in Seattle includes many DfD elements. The building uses non-toxic materials and has a structure that can be easily dismantled. Additionally, it has a lifespan of 250 years through thoughtful design.

Highlights:

- Non-toxic materials

- Easily demountable structure

- Extended lifecycle

Future Prospects and Innovations

The future of designing for deconstruction looks promising, particularly as technology and public awareness continue to advance. Emerging trends such as 3D-printed buildings and bio-based materials are likely to impact the sector significantly.

3D-Printed Structures

3D printing technology offers the potential to create structures with fewer materials and less waste. Additionally, components produced through 3D printing can be designed for easy disassembly and reuse.

Bio-Based Materials

Materials such as mycelium, bamboo, and hemp are gaining attention for their environmental benefits. These materials are not only sustainable but can also be engineered for adaptability, making them suitable for DfD.

Circular Economy

The concept of a circular economy, where resources are continuously reused and recycled, will profoundly influence future architectural practices. As DfD becomes more mainstream, we can expect a greater alignment between architecture and the principles of the circular economy.

Conclusion

Designing for deconstruction is an essential component of sustainable architecture. By rethinking how we build and, importantly, how we unbuild, we can create structures that are kinder to our planet and beneficial to our communities. While challenges exist, the benefits—environmental, economic, and social—make it a worthy endeavor.

As we continue to innovate and adapt, the principles of DfD will increasingly become the standard. Together, we can build a more sustainable future, one building at a time. By adopting the practices and principles outlined here, we can contribute to a world where buildings serve as resources for tomorrow, not waste for today.

Let’s embrace this new paradigm and lead the way in sustainable, deconstructable design. Have you thought about how your next project could incorporate these principles? The time for action is now.